In sport, there is usually only one winner. With this timekeeping project for swimming competitions, there are three winners: the client, an international electronics company; the client’s customers (operators, organisers) and even the swimmers. With new ideas for profile contour, surface structure and inline machining, mobil Kunststoffprofile took development of the stop plates further. The result: A win-win-win solution or as sports people say, a classic hattrick.

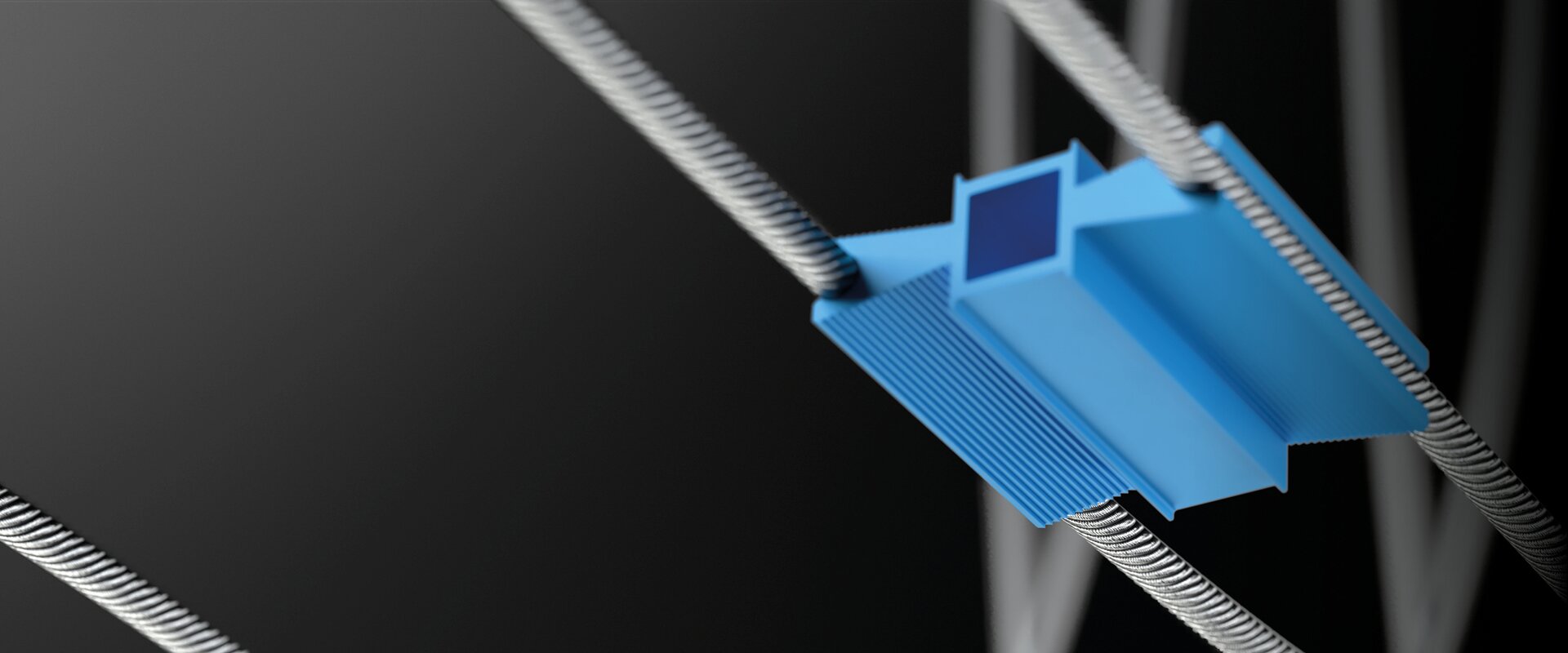

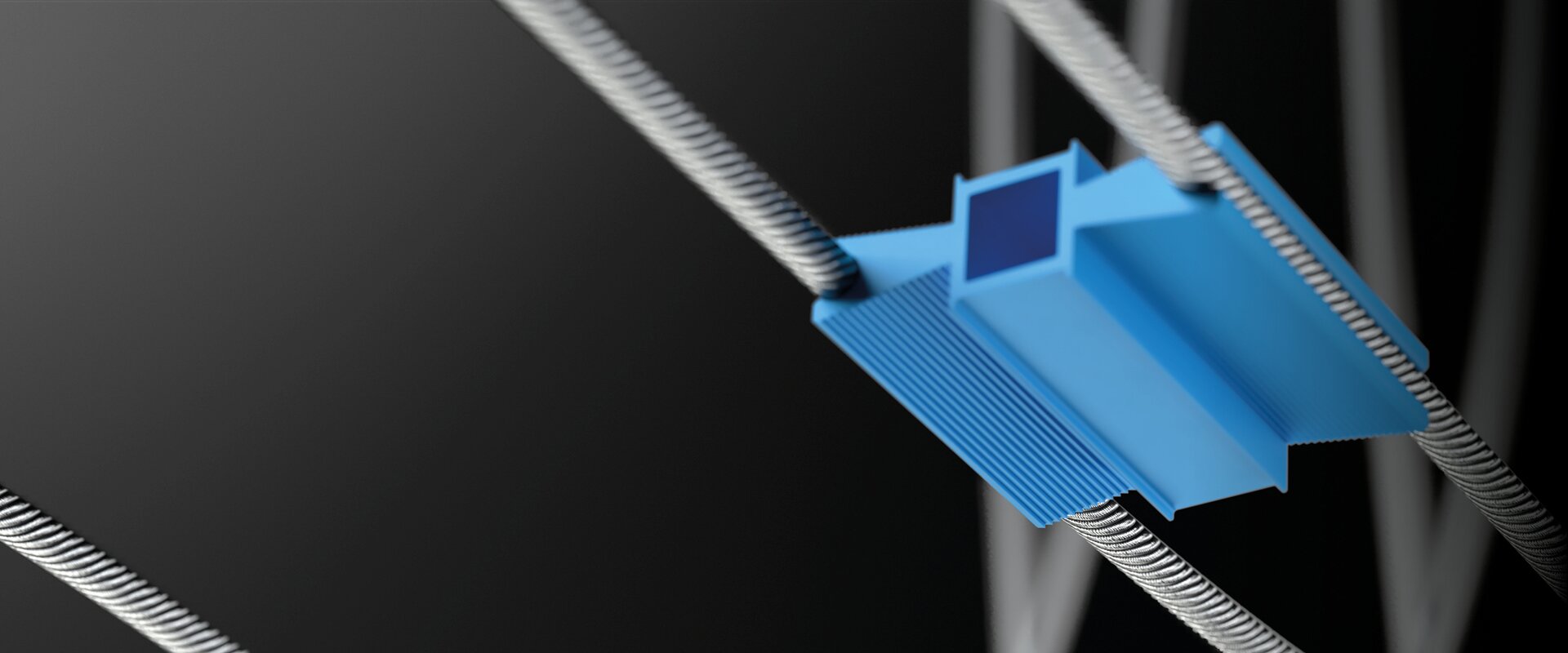

The customer has been producing timing instruments for sports such as swimming for a number of years. The most important components for achieving an accurate timing system in swimming are the stop plates. The swimmers touch these plates, which are around 2.4 metres wide and 0.9 metres high, when they turn or finish a swim. This triggers an electronic timekeeping pulse. Until now, the customer has made these stop plates from commercially available roller shutter slats. The customer drilled holes in these slats by hand, stuck them together and painted them with anti-slip paint to finish them off.

The customer turned to mobil Kunststoffprofile with the aim of reducing their own workload. The slat requirements were specified in a drawing. These findings resulted in a profile contour that offers lateral stability and a surface structure that replaces the anti-slip paint, providing the swimmer with sufficient grip without the potential for injury. A profile solution with tangible customer benefits. The openings for the water flow created by inline machining optimise the flow behaviour. The material was specially chosen because the plastic has to be able to tolerate chlorinated water.

Benefits for swimmers

Improved grip of the new slatted surface. The openings in the slats provide better flow conditions; swimmers in different lanes no longer put one another at a disadvantage.

Benefits for users

Increased service life of the stop plates due to the elimination of the anti-slip paint. Approx. 30% reduction in weight of the stop plates. Impressed competitors.

Benefits for manufacturers

Significant reduction of own assembly work due to omission of drilling and milling work; the slats only have to be pushed together and the frame assembled. Satisfied customers and image boost.