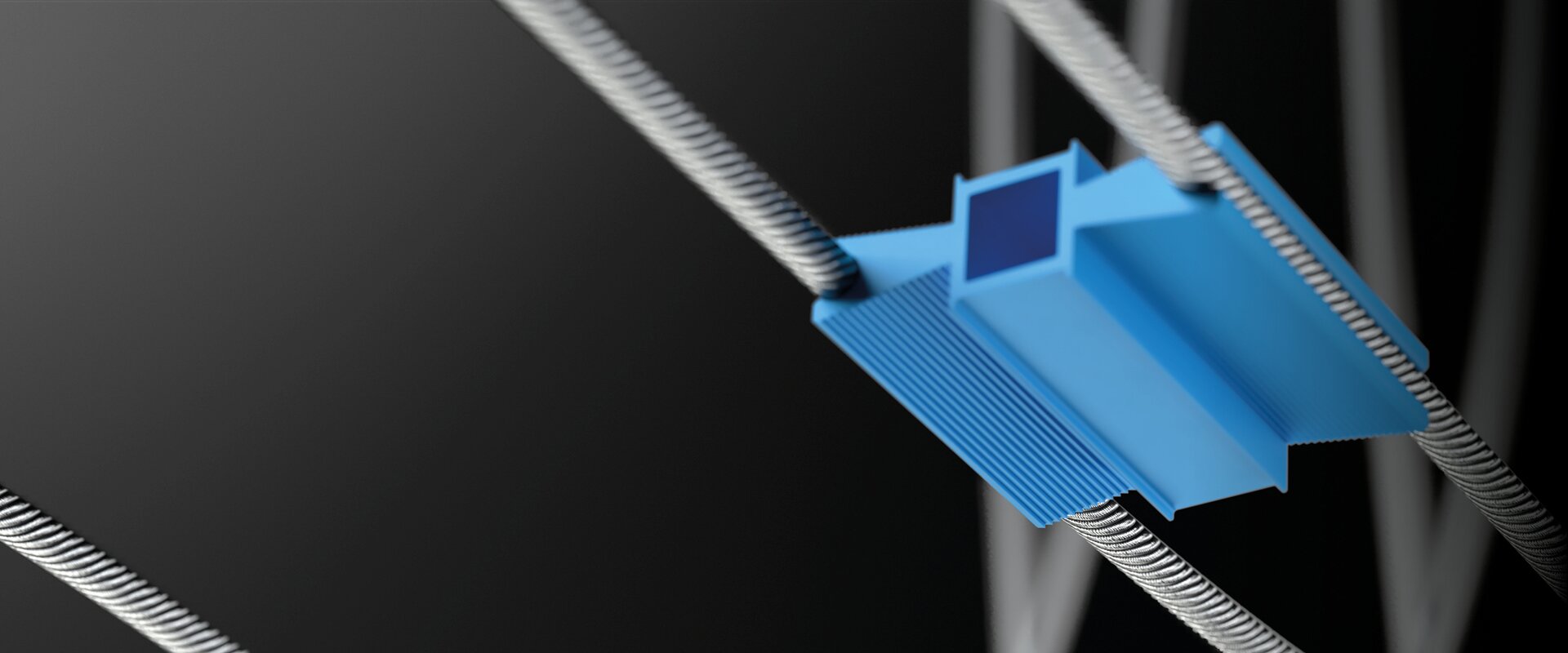

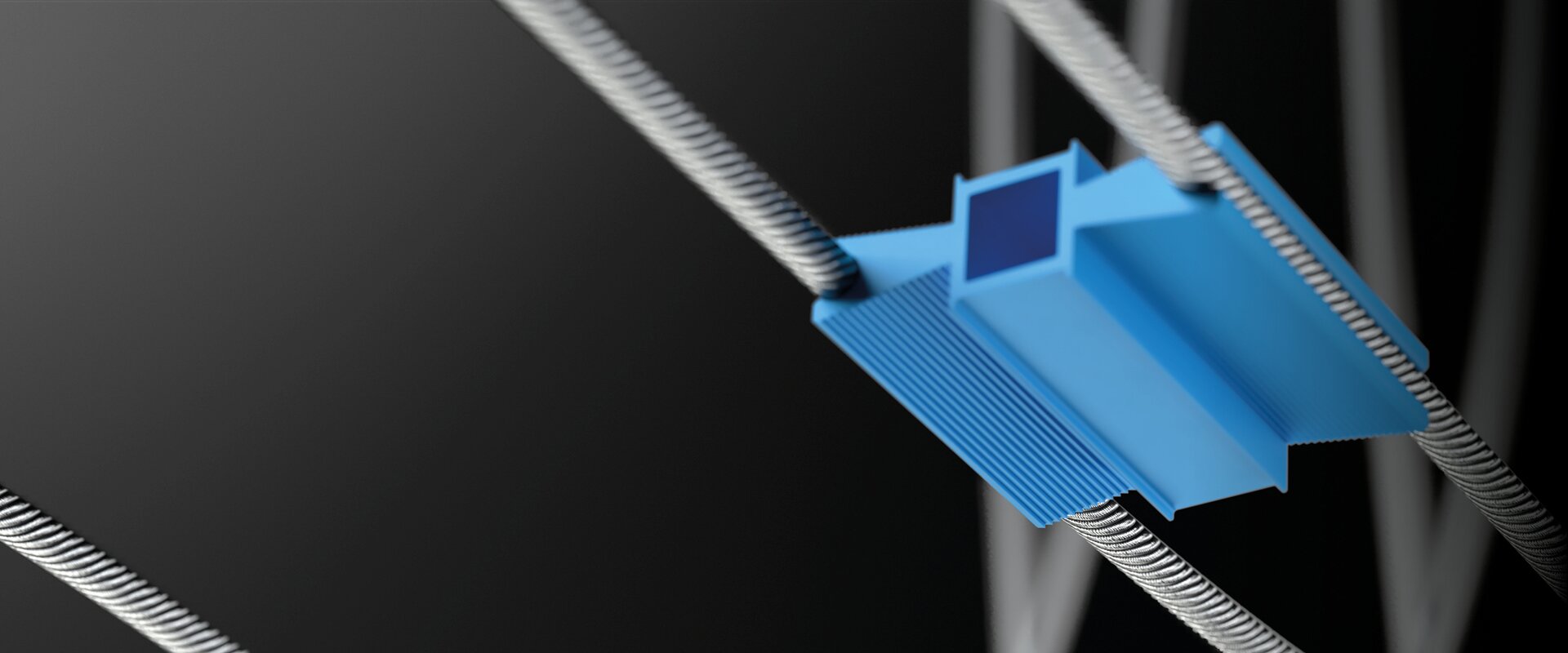

Water is a natural element that seeks out its own path. To keep water where it belongs on the building site – outside the concrete structure – waterproof concrete is used in combination with joint seals at the construction and expansion joints. A manufacturer of elements for building protection had a product idea and found an experienced implementation partner in mobil Kunststoffprofile. The result: a patented and commercially successful sealing system.

The customer, an innovative small company without its own design and development department, had a ground-breaking idea – a joint seal that not only achieves a high sealing effect, but is also equipped with a sophisticated injection system. The customer lacked a development and manufacturing partner with the corresponding material, design and production expertise. They found it in mobil Kunststoffprofile.

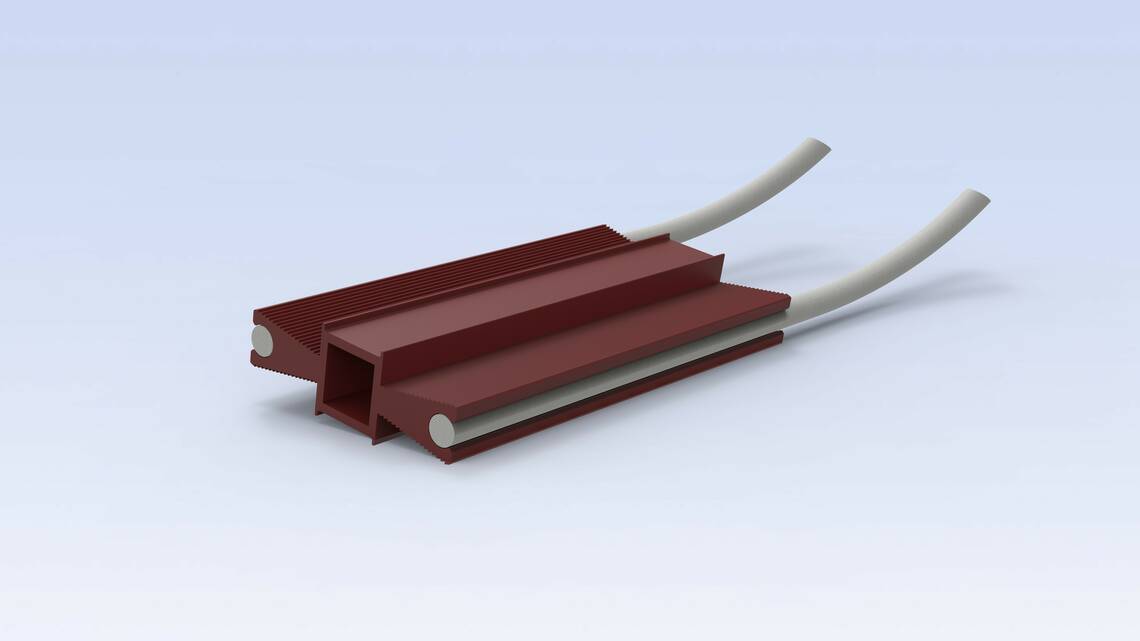

First of all, the requirements for the new building element were precisely specified – approval for the drinking water area, compatibility with concrete, inline processing of drill holes and attachment of separating cord, as well as direct usability on the construction site without the need for further preparatory work. mobil Kunststoffprofile designed the construction element and set up production according to these requirements. The self-developed, integrated drilling unit was one of the ideas that really paid off. It allows different water-stop dimensions to be machined, thus keeping tooling costs down.

Launch of a successful product family

The new building sealing sets standards and has resulted in annual sales increases of 50%.

Optimised tool costs

The production of a master tool reduces the costs of further developments by a considerable 30%.

Reduced transport costs and complexity

mobil Kunststoffprofile delivers to the customer's licensees or directly to the construction site.