Customer-focused work is when it's not the product that comes back, but the customer. Like this electronics company that manufactures stop plates for timing swimming competitions. mobil Kunststoffprofile had already optimised the slats and was commissioned to redesign the rubber profile in this project. The profile solution creates measurable benefits for the manufacturer and its customers.

The incentive behind the redesign of the profile was that installing the standard profile using manual riveting and gluing had always been very time-consuming. Sealing the sides with a PUR adhesive took two days, including drying, and blocked important work areas. The small, plastic box which was attached for the connection sockets was visually unattractive due to the difference in material.

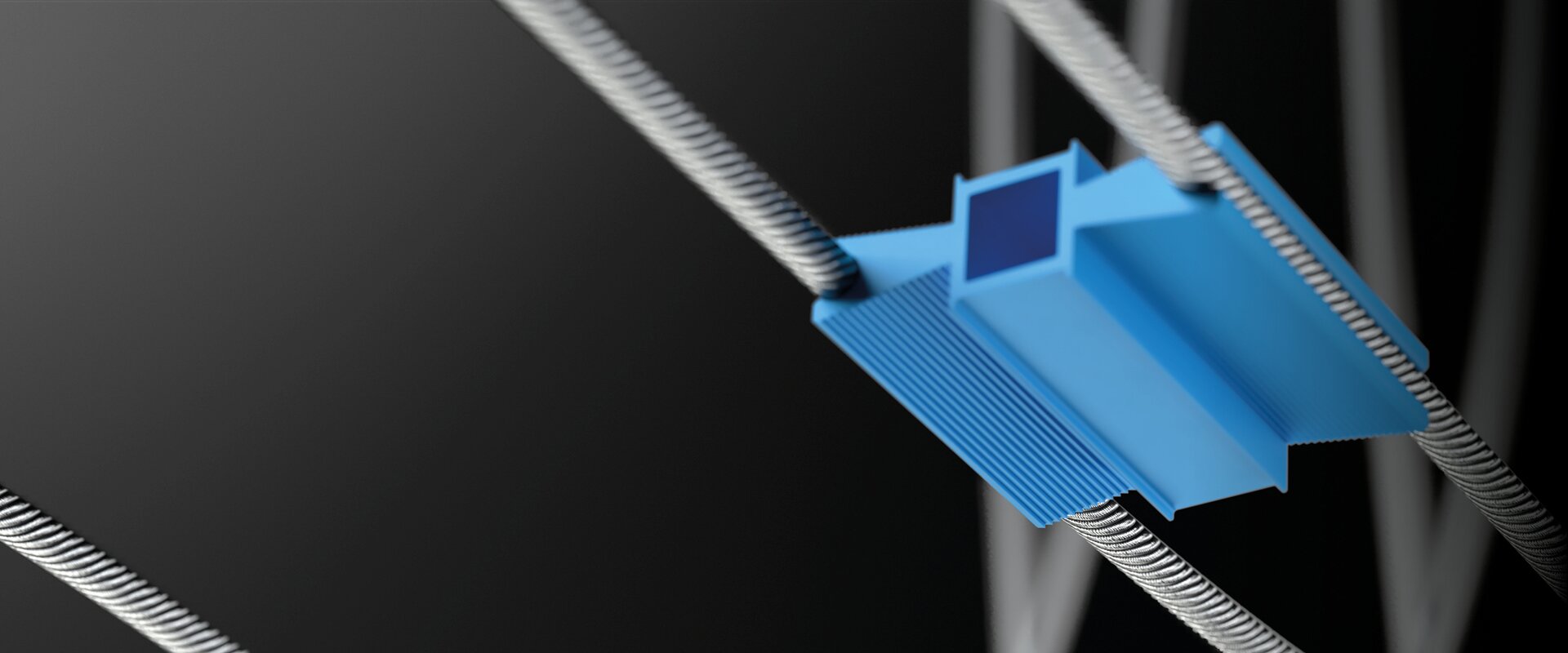

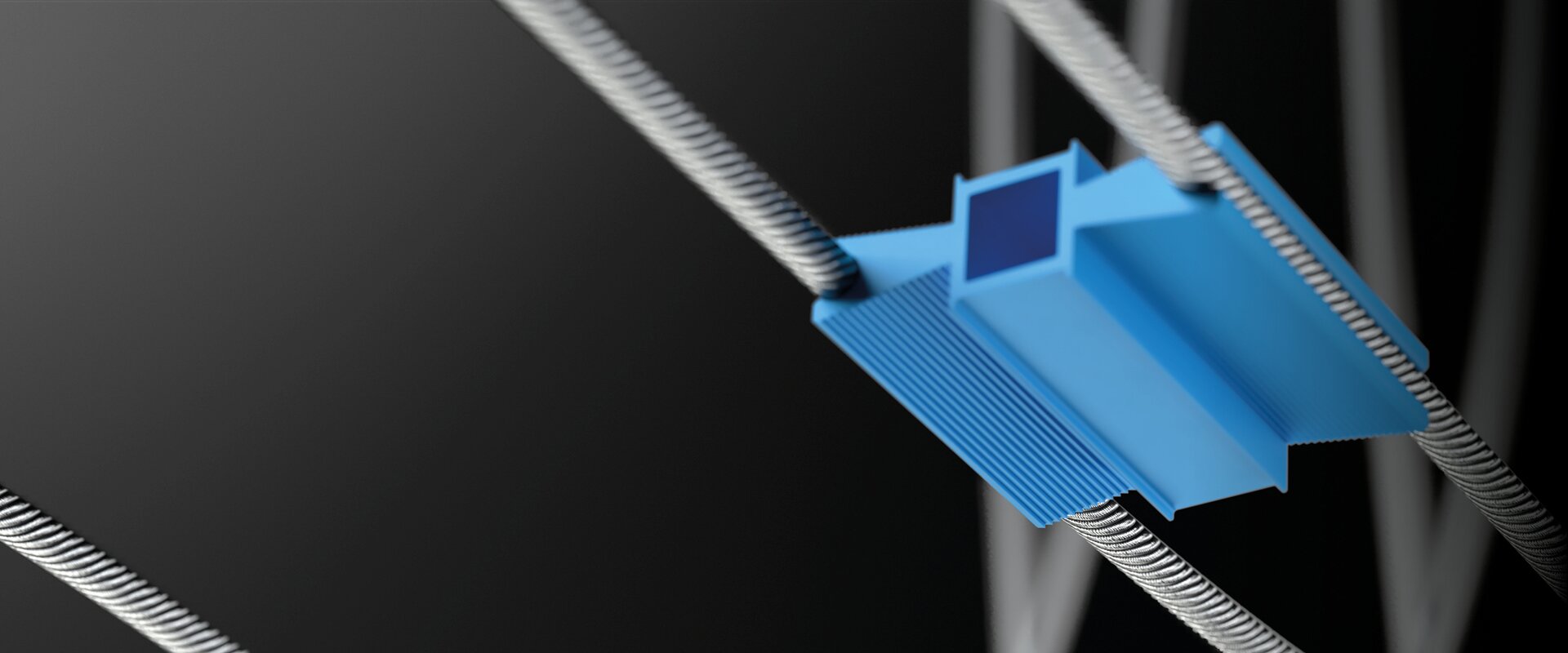

By working together, brainstorming, and using drawings and CAD, an individual overall solution emerged. The rubber profile is designed to clip effortlessly into the rail and the anchorage maintains the load when the stop plate is removed from the pool. Sealing the edges with adhesive is no longer necessary, thanks to end caps that are moulded on by means of corner vulcanisation.

Simplified assembly

Time-consuming, laborious and error-prone assembly steps such as gluing are no longer necessary

Customised production

The customer orders and receives the finished elements at the desired length (1890 mm or 2400 mm).

Impressive appearance

The new component gives the stop plates a harmonious and professional overall appearance.