The shower is a place of well-being. This includes being able to close the door easily and safely – without having to sacrifice appearance or quietness. A leading manufacturer of shower systems developed an intricate door profile to meet this demand and found the ideal implementation partner in mobil Kunststoffprofile AG. The tool concept for the coextrusion profile not only fulfils the technical and sensory requirements, but also enables easy assembly.

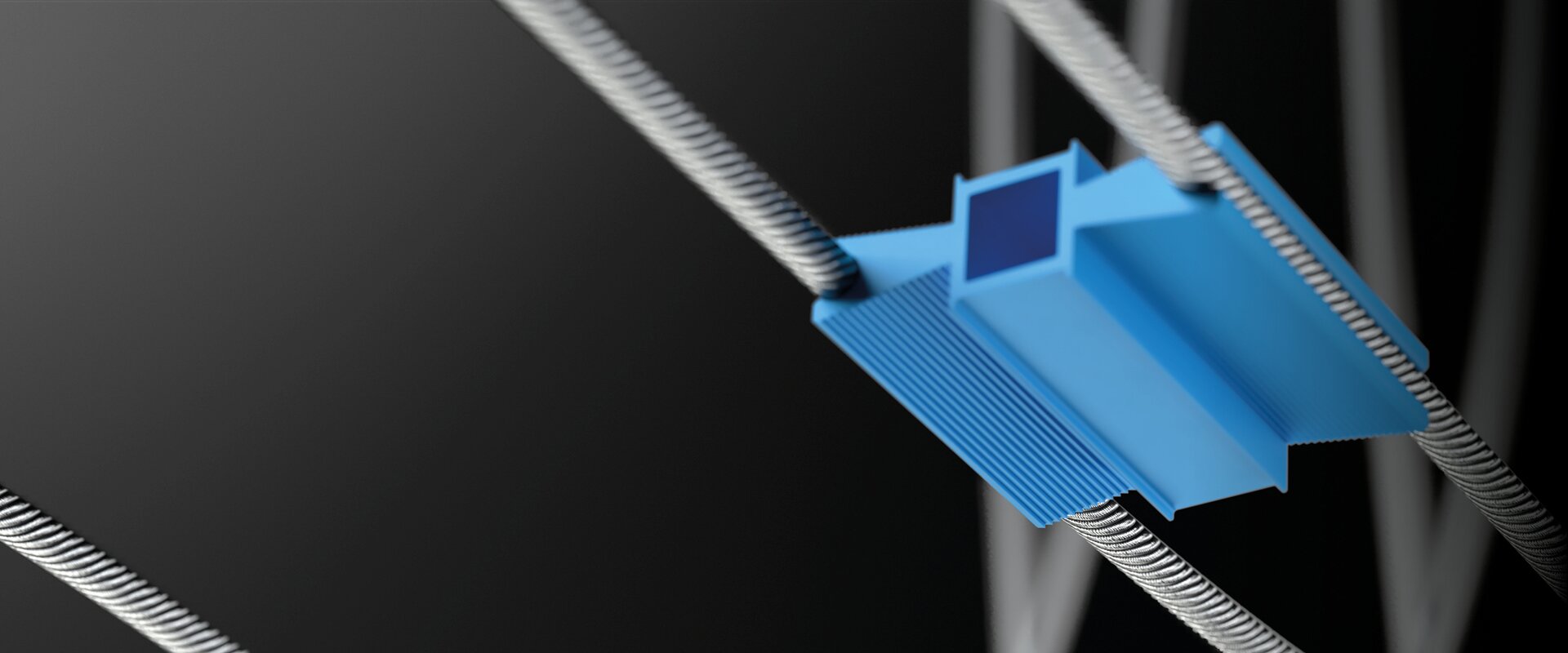

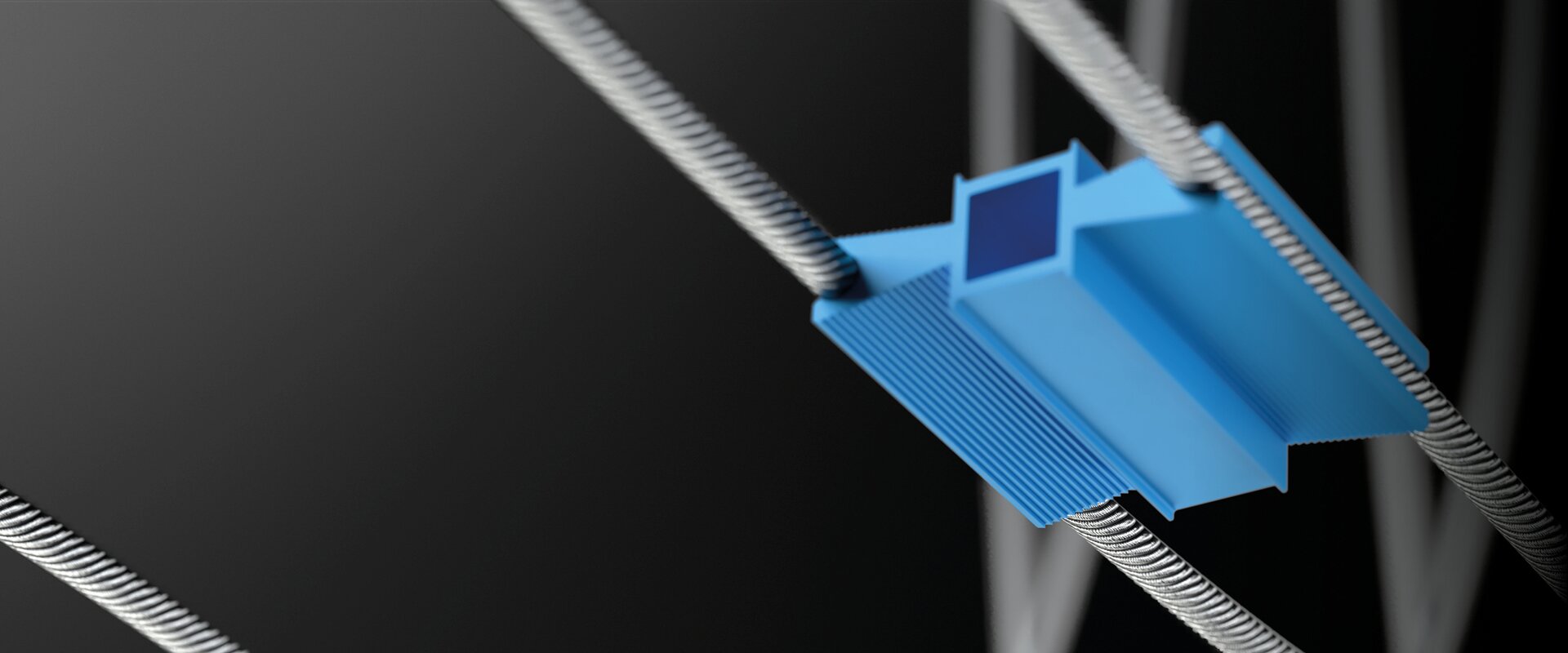

The very tight tolerance specifications of this door profile challenged our tool developers in tool design and processing. For example, the hollow chamber with its very thin wall thickness of 0.4mm must cause very little resistance when closing the door, while small cams are there to prevent it from slipping. In addition, the soft component needed to be sharpened and distributed evenly in three places.

The tool concept was successfully implemented thanks to the intensive cooperation right from the start between the customer and the design, production and quality assurance departments. Hard and soft PVC was the favoured choice of material. An efficient Swiss solution for a quality Swiss product.

Functional system

The tool concept enables fine profile geometry with different materials – for an exceptional shower experience.

Successful commercialisation

The customer received a market-ready solution that started so well that further profiles have already been realised.

Head start

Thanks to the joint know-how, new projects can be implemented in a timely manner.